Client Profile

The company Kaufland Fleischwaren exists since 1985 and operates a total of five highly modern production companies for meat and sausage products in Germany and the Czech Republic. About 3.000 employees produce more than 350 meat and sausage specialties for the own brand K-Purland and process around 850.000 pigs and 60.000 cattles annually. Kaufland Fleischwaren belongs to Kaufland. Kaufland and the food retailer Lidl as well as other companies are part of the Schwarz Group, based in Neckarsulm, who is the largest retailer in Europe and the fourth largest trading company in the world with an annual turnover of about € 90 billion.

Project

In 2012, Kaufland Fleischwaren started with the company-wide roll-out of the Continuous Improvement system “EVO”, which had already been introduced at the plant in Möckmühl, Germany in the year 2008. For the roll-out, extensive training measures were implemented on all hierarchy levels, combined with the simultaneously establishment of an internal Lean organization. In order to support the further implementation and expansion of the EVO system in all company segments, Kaizen Institute was assigned with the following project scope:

Definition of a role and requirement profile for managers and EVO supporters

- Training of the necessary role perception in the EVO organization

- Consultation and coaching of these skills for the practical application

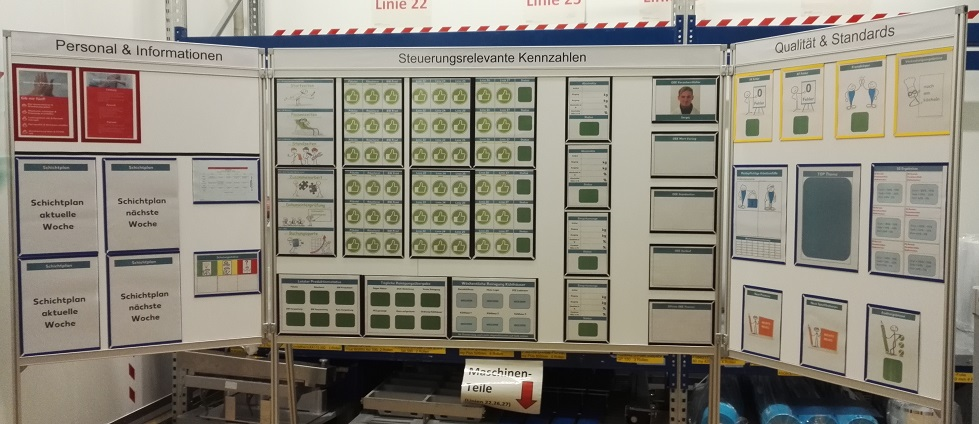

Introduction of a shopfloor management system in all plants

- Implementation of a regulatory cycle

- Guidelines for target achievement measurements

- Ensuring sustainability

- Dissemination of standards

- Involvement of employees

“The implementation of shopfloor management, was another important step within our EFQM process and made us the benchmark leader in the meat processing industry.”

Ralph Dausch – CEO

Kaufland Fleischwaren, Germany

Our Approach

- Accomplishment of basic training courses related to shopfloor management

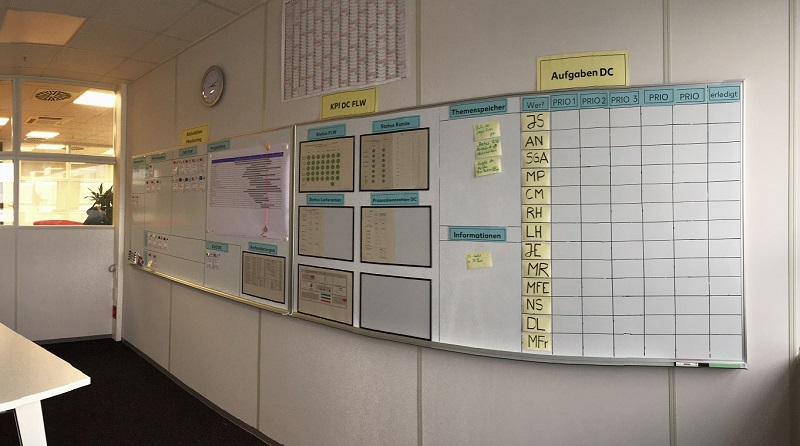

- Definition of information flows and the communication structure within the plants and across the enterprise

- Development of shopfloor-boards including key figures from the shift leader and employee level up to the management level

- Securing a structured communication within the various hierarchy levels

- Coaching in order to sustainably consolidate the work with key figures & goals, PDCA cycles and Gemba walks in the organization

- Implementation of 5S in the office within the central area

Key Results

- Despite the shortened project duration from 12 to 8 months, all planned measures could be implemented and terminated on schedule

- Improvement of the information flow and reduction of the meeting quantity by introducing an appropriate shopfloor management

- Strong identification of the employees with the targets of the company/ factory/department through the targeted derivation of key figures within the employees’ scope of influence

- Through the implementation of visual management, a very fast reaction time in case of deviations or issues was achieved

- Active involvement of all employees in the EVO system through the timely and sustainable implementation of improvement measures with the help of PDCA cycles

See more on Process Manufacturing

Find out more about improving this business area