Problem

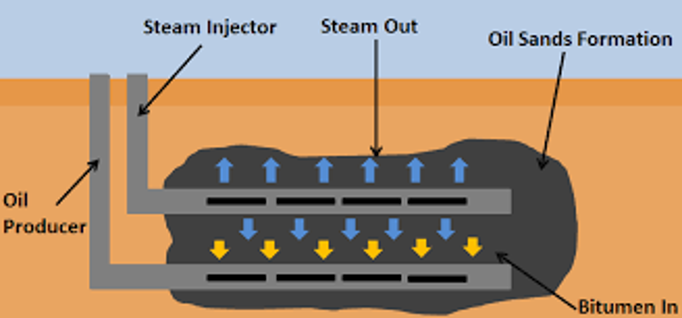

Our client, a leading independent oil producer producing oil from the Canadian Oil Sands using SAGD process from one of its operations, needed to study their maintenance turnaround in order to reduce the duration of their future turnarounds. The event was scheduled for 21 days, but the actual duration surpassed the plan by 4 days.

Root causes

- Variation in work execution due to lack of standards and systems.

- Inadequate use of techniques to complete work faster, lack of breakthrough ideas in changing the way of working, lack of readiness on alternative solutions when faced with obstacles.

- Other than the major lessons learned, improvement opportunities from past turnaround events were not taken advantage of, events were managed in a reactive fashion.

Solution approach

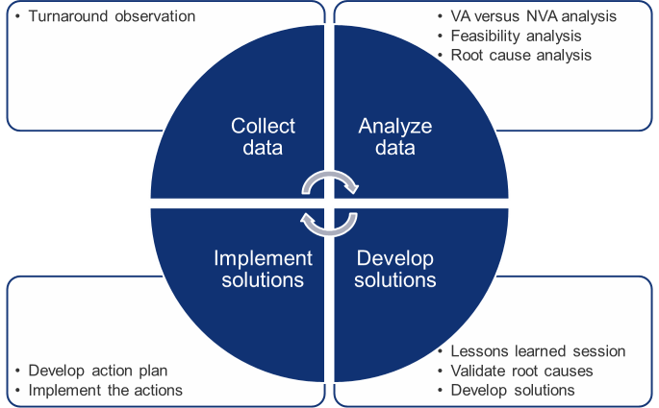

- Turnaround observation to identify non-value added activities (improvement opportunities) and positive observations.

- Root Cause Analysis using 3C approach to identify root causes and counter measure for the identified improvement opportunities.

- Lessons learned session to document the lessons learned and also to validate the root causes of problems that occurred.

- Develop action plan to eliminate/reduce the non-value added activities from future turnarounds.

Benefits

- 150+ improvement opportunities were identified and initiated for implementation to attain the budgeted duration as well as to reduce the duration of future turnarounds below 21 days.

- 140,000 bbl. of increased production due to attainment of budgeted duration (21 days) will result to a saving of $8M.